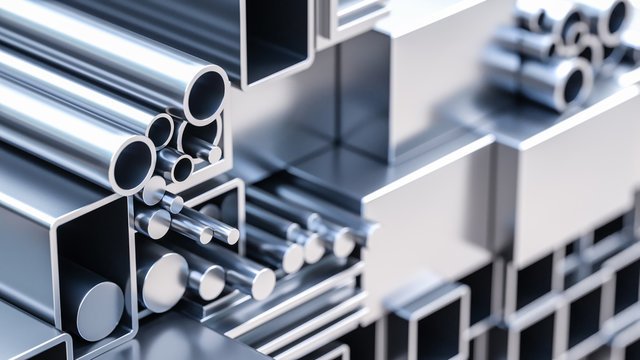

ALUMINIUM ROUND BARS

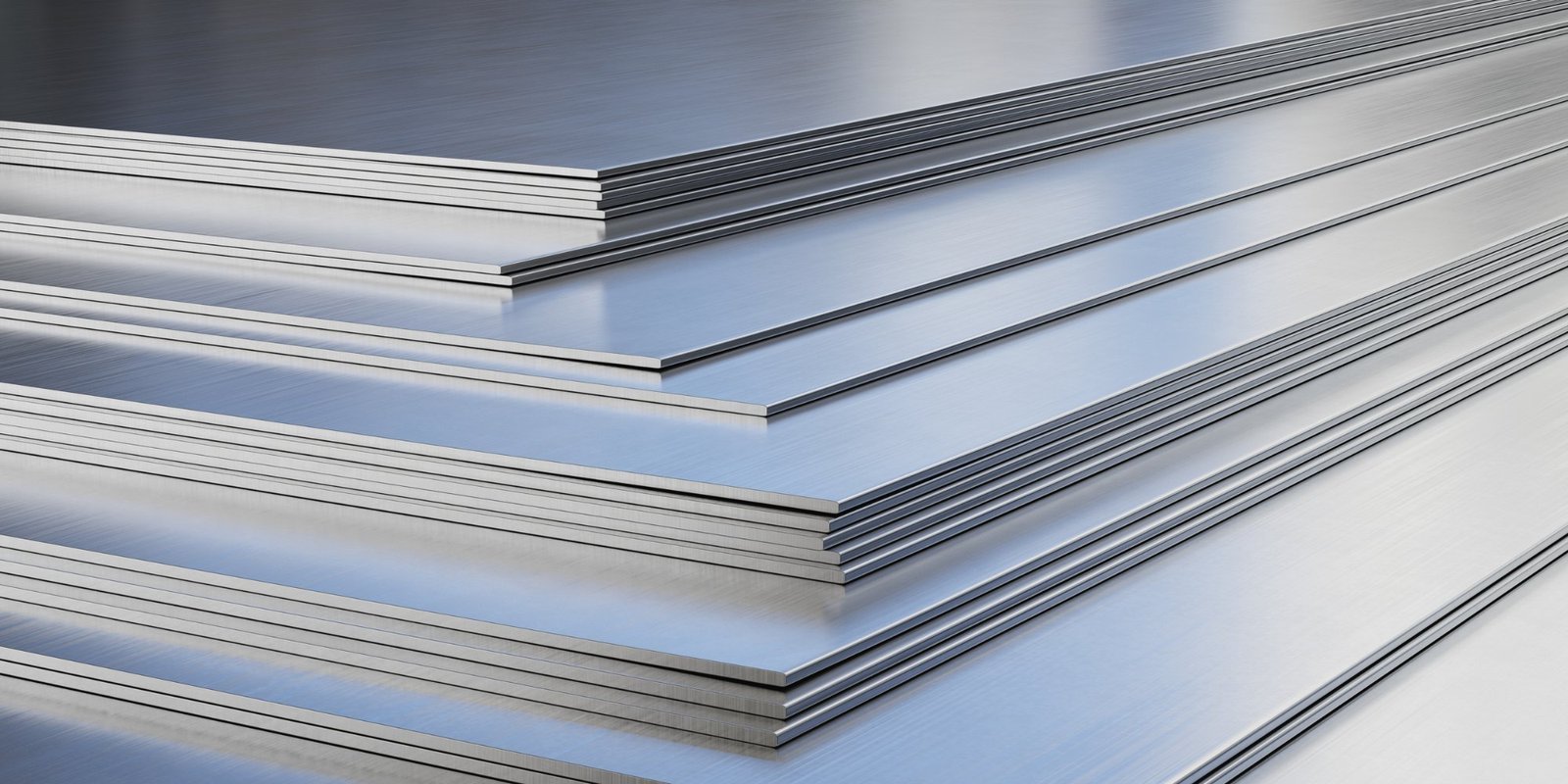

ALUMINIUM ALLOYED SHEETS & PLATES

ALUMINIUM ROUND PIPES

ALUMINIUM FLAT & SQUARE BARS

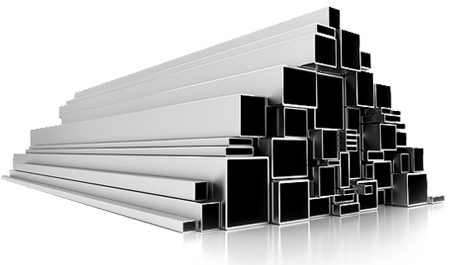

ALUMINIUM SQUARE & RECTANGULAR TUBES

ALUMINIUM CHEQUERED SHEETS

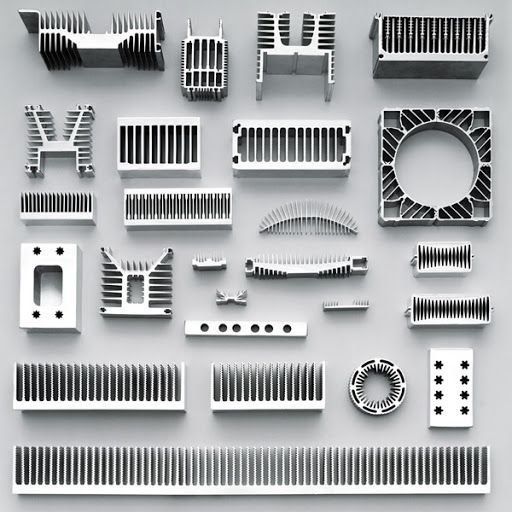

ALUMINIUM EXTRUDED SECTIONS

STAINLESS STEEL RODS

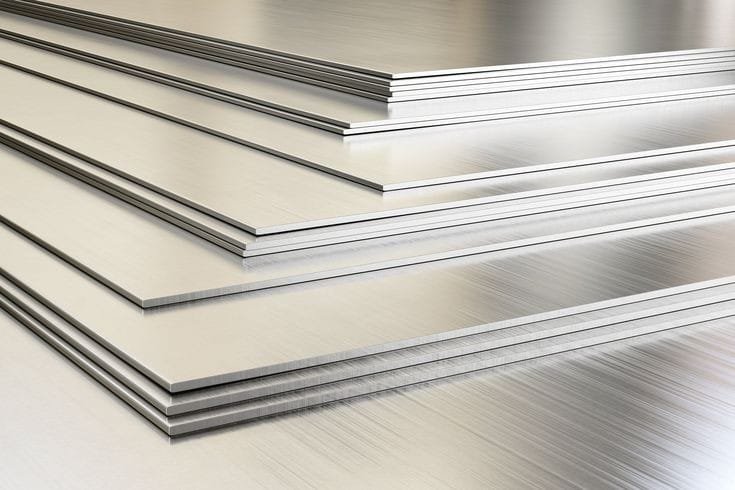

STAINLESS STEEL SHEETS

Aluminium Extruded Bars in variety of alloys & sizes.

Aluminium Rolled Sheets & Plates in a variety of alloys, thicknesses and dimensions.

Aluminium Extruded Pipes in a variety of alloys & sizes.

Aluminium Extruded Bars in a variety of alloys & sizes.

Aluminium Extruded Tubes in a variety of alloys & sizes.

Aluminium Rolled Chequered Sheets & Plates in a variety of alloys, thicknesses, designs and dimensions.

Aluminium Extruded Customized Sections in varirty of alloys, shapes and sizes.

Stainless Steel Rods in variety of shapes and grades.

Stainless Steel Sheets in variety of grades.

ABOUT BANSAL METALS

ABOUT BANSAL METALS

Our decades of experience in the metal industry sets us apart and also enables us to possess in-depth knowledge of market trends, product specifications, and supplier networks.

We pride ourselves on our unwavering commitment to sourcing only the highest quality metals from the most reputable mills worldwide. Our stringent selection process ensures that every product we offer meets the strictest standards of excellence, guaranteeing superior performance and reliability for our clients. With our relentless commitment to quality assurance, you can trust that every product you receive from us is of unparalleled quality and reliability, and can be rest assured that your projects will be built to last.

We believe you’re not just a customer – you’re a valued partner, and your satisfaction is our ultimate goal.”

MISSION

At Bansal Metals Private Limited, our mission is to be the premier partner in the global metal trading industry, committed to delivering exceptional value and service to our clients, suppliers, and stakeholders.

Guided by integrity, innovation, and sustainability, we strive to exceed expectations by providing reliable access to high-quality metals, fostering long-lasting relationships, and driving positive impact in the communities we serve. With a relentless focus on excellence we aim to be the trusted leader in metal trading, empowering growth and success for all.

We believe in going beyond transactions to build partnerships based on trust, communication, and mutual success. From the initial inquiry to post-sale support, we prioritize open dialogue, transparency, and personalized service to ensure that every interaction exceeds expectations.

OUR MANAGMENT TEAM

Mr. Gian Chand Bansal

A visionary leader with an eye for strategy and a heart for innovation, has charted the course for the organization with wisdom, foresight, and unwavering resolve.

His ability to inspire, empower, and lead by example has cultivated a culture of creativity, collaboration, and continuous improvement—a culture that serves as the bedrock of our success.

Mr. Sahil Bansal

A technical virtuoso and master of innovation, has pushed the boundaries of what’s possible, delivering solutions that defy expectations and redefine industry standards.

The unwavering commitment to technological excellence, coupled with his relentless pursuit of innovation, has fueled the organization’s evolution and positioned it as pioneers in the field.

Mr. Aman Bansal

A marketing maven and brand evangelist, has captivated audiences, driven engagement, and elevated the brand to new heights of visibility and relevance.

His keen understanding of market dynamics and consumer behavior has enabled, to connect with audiences on a deeper level, forging lasting relationships and driving sustained growth.

Our Products

Industries we serve

FREQUENTLY ASKED QUESTIONS (FAQ)

In the context of aluminum, temper refers to the specific treatment that the aluminum alloy has undergone to achieve certain mechanical properties, such as strength, hardness, and ductility. The temper designation is critical because it affects how the aluminum behaves during fabrication and in its final use.

Tempering involves processes like ageing, heat treatment, cold working, or a combination of both. Aluminum alloys can be softened, hardened, or have their properties enhanced based on the required application.

The primary difference between the T6 and T651 tempers in aluminium alloys lies in the stress-relief process used after heat treatment.

T6 (Solution Heat-Treated and Artificially Aged):

- In the T6 temper, the aluminium alloy has been solution heat-treated and then artificially aged to reach its maximum strength.

- This temper results in high strength but can sometimes introduce residual stresses due to the heat treatment process, which can cause slight warping when machining.

T651 (Solution Heat-Treated, Stress-Relieved by Stretching, and Artificially Aged):

- The T651 temper is similar to T6, but with an additional stress-relieving step. After solution heat treatment, the material is slightly stretched (usually about 1-3%) to relieve internal stresses.

- The stretching process reduces the likelihood of distortion during machining, making T651 particularly suitable for applications requiring precision, such as large machine parts.

- This temper is especially common in thick plates of aluminium.

The melting point of aluminium alloys varies depending on their composition and the types of alloying elements they contain. However, most aluminium alloys fall within a general melting range of 463°C to 671°C (865°F to 1,240°F).

Here are the melting points of some common aluminium alloys:

- Pure aluminium (Al 99%): 660°C (1,220°F)

- 6061: 580°C to 650°C (1,076°F to 1,202°F)

- 7075: 477°C to 635°C (890°F to 1,175°F)

- 2024: 502°C to 638°C (936°F to 1,180°F)

- 5052: 607°C to 649°C (1,125°F to 1,200°F)

The presence of alloying elements like silicon, copper, magnesium, and zinc alters the melting range for each alloy, often lowering it compared to pure aluminium.

The density of aluminium is typically 2,730 kg/m³ (or 2.73 g/cm³) in metric units. In imperial units, it is approximately 0.0975 lb/in³.

Yes, aluminium alloy 6061 is anodizable. It is commonly anodized to improve corrosion resistance, enhance its appearance, and increase surface hardness. Anodizing 6061-T6 creates a durable, protective oxide layer on the surface of the alloy.

Yes, Aluminium Alloy 6082 is anodizable. Like 6061, it responds well to the anodizing process, which enhances its corrosion resistance and surface hardness. However, anodizing 6082 can result in a slightly different finish compared to other alloys like 6061 due to its higher silicon content. The final appearance can vary, but it generally yields a good-quality anodized surface, commonly used for structural applications and components requiring durability.

Yes, aluminium alloy 5052 is anodizable. It is particularly known for its excellent corrosion resistance, especially in marine environments, and anodizing enhances this property further. However, the anodized finish on 5052 tends to be less bright and uniform compared to alloys like 6061 or 6082 due to its higher magnesium content. The surface may appear more matte or greyish after anodizing, but it still offers a strong, protective oxide layer that improves both durability and appearance.

The density of stainless steel generally ranges from 7,750 kg/m³ to 8,050 kg/m³ (or 7.75 g/cm³ to 8.05 g/cm³). This variation depends on the specific grade or alloy of stainless steel.

Common Stainless Steel Grades:

- 304 Stainless Steel: Approx. 8,000 kg/m³ (8.0 g/cm³)

- 316 Stainless Steel: Approx. 8,000 kg/m³ (8.0 g/cm³)

- 410 Stainless Steel: Approx. 7,750 kg/m³ (7.75 g/cm³)

These values can be used for calculating the weight of stainless steel components and for engineering purposes.

The most commonly used stainless steel grades for food-grade applications are 304 and 316.

- Grade 304 (also known as 18/8 stainless steel): This is the most widely used food-grade stainless steel due to its excellent corrosion resistance, durability, and ease of cleaning. It contains 18% chromium and 8% nickel, making it resistant to most acids and alkaline solutions, which are common in food processing environments.

Grade 316: This grade contains 16% chromium, 10% nickel, and 2% molybdenum, which offers enhanced resistance to corrosion, especially against chlorides (salts). It is often used in environments where the food or cleaning processes involve salty or acidic conditions, such as in coastal areas or for processing certain foods like seafood.